Effective bulldozer protection in high-humidity environments

With the onset of the rainy season and the increase in precipitation, highly humid surroundings become more frequent. Bulldozers operating in these conditions for extended periods can encounter a variety of problems. These include performance degradation, accelerated corrosion and electrical shorts. These problems can lead to frequent equipment failures and have a potential impact on bulldozer service life.

Effects of elevated dampness settings

Effects of elevated dampness settings

These effects, on personnel and machinery are significant. High moisture areas often experience heavy rainfall and are generally located in mountainous regions. These areas are prone to natural disasters such as landslides and mudslides. Such conditions pose a safety risk for operators and bulldozers alike.

Long-term operation of bulldozers in this kind of climate can easily cause a series of problems:

Failure rate: It’s well-documented that operating heavy machinery like bulldozers in damp sceneries can lead to various problems. These issues can affect the reliability, availability, and maintainability (RAM) of the equipment.

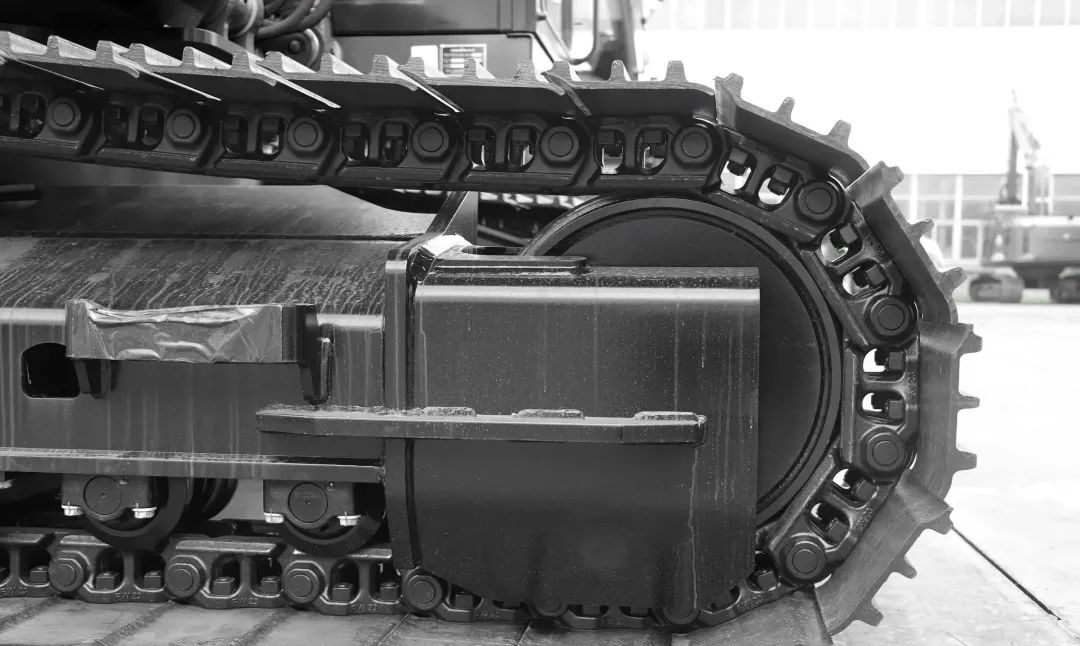

Rust and Deterioration: Components of a bulldozer are susceptible to the damaging effects of rust and corrosion. When these elements have severely corroded, disassembling them becomes a challenging task, leading to a direct impact on the efficiency of repair work. The insidious nature of rust and corrosion can cause operational parts to seize up, diminishing the robustness of connection fasteners. This can result in fractures and, in extreme cases, even lead to mechanical mishaps.

Short Circuits: It can also lead to compromised electrical connections and diminished insulation in electrical components. This can result in various electrical malfunctions, including line breaks, short circuits, and the burning out of solenoid valve coils.

Safety Recommendations for Equipment Maintenance

I. Site Management Enhancement

In extremely wet conditions, the management of bulldozer operation sites should prioritize protection against rain, moisture, and lightning.

· Electrical switches and distribution cabinets should be equipped with rain and moisture-proof measures.

· Low-voltage distribution rooms should be fitted with lightning protection devices as per regulations.

· In the event of severe thunderstorms, operations should be halted, and machinery should be moved to a safe location.

· Temporary parking spots should be chosen with care, ideally far from gullies, rivers, and steep cliffs.

The ground foundation should be compacted, peripheral drainage ditches should be dug, side slopes should be managed, and surrounding weeds should be cleared.

II. Equipment Safety Control

It would be beneficial to conduct regular inspections to ensure that the lubricant and hydraulic oi temperature control devices are functioning properly. It's also important to verify the reliability of monitoring systems and safety mechanisms, such as torque limiters, limit switches, and emergency brake switches. Should any hazards be discovered during these inspections, they ought to be remedied promptly to maintain safety. The use of equipment that is found to be faulty should be avoided to protect everyone's well-being.

III. Maintenance Focus

In wet conditions, it’s important for bulldozer operators and mechanics to give special attention to daily maintenance, particularly of the hydraulic and electrical systems.

· Hydraulic System: It's advisable to perform regular checks for any leaks in pipelines and radiators, ensure the fan is operating correctly, and monitor both the quantity and quality of the hydraulic oil. Regular cleaning of the hydraulic oil tank can help minimize internal contamination and preserve its cooling efficiency. Consistency in using the same type of hydraulic oil is key, and any contaminated or substandard oil should be promptly replaced. Additionally, changing the hydraulic oil filter on a regular basis is essential to maintain a clean and unobstructed oil flow.

· Electrical System: Routine inspections for loose connections, wire oxidation, or corrosion are recommended. It's also important to set the generator regulator accurately and adjust the charging current as needed. Keeping the battery's exterior clean, ensuring the battery socket and cables are securely connected, adding distilled water when necessary and maintaining clear ventilation holes are all part of good battery maintenance.

IV. Special Protective Measures

It's important for bulldozer operators to dehumidify and maintain their equipment promptly to prevent interior damage from moisture and airborne chemicals.

· Dehumidification Maintenance: After operating the equipment, maintenance tasks should include thorough cleaning, securing components, and applying lubricant. Electrical components require special attention to ensure moisture is removed without causing damage. This can be archived by using dry, compressed air or other moisture-absorbing methods that do not leave residue.

Facility Configuration: To mitigate the impact of high-humidity, construction sites should be equipped with rain/poof sheds, and bulldozers should have rain-proof covers. However, avoid wrapping bulldozers in plastic sheets, as this can hinder heat dissipation.

By understanding the challenges of a wet environment and implementing these protective measures, it is possible to maintain the effectiveness of bulldozers to ensure normal operation of their full capabilities.