01

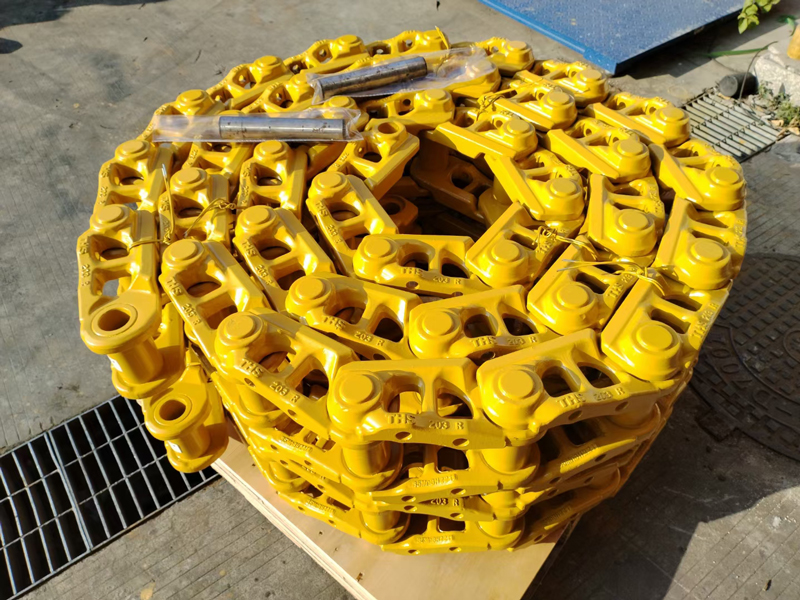

High Quality D65 Sealed Track Link Assembly

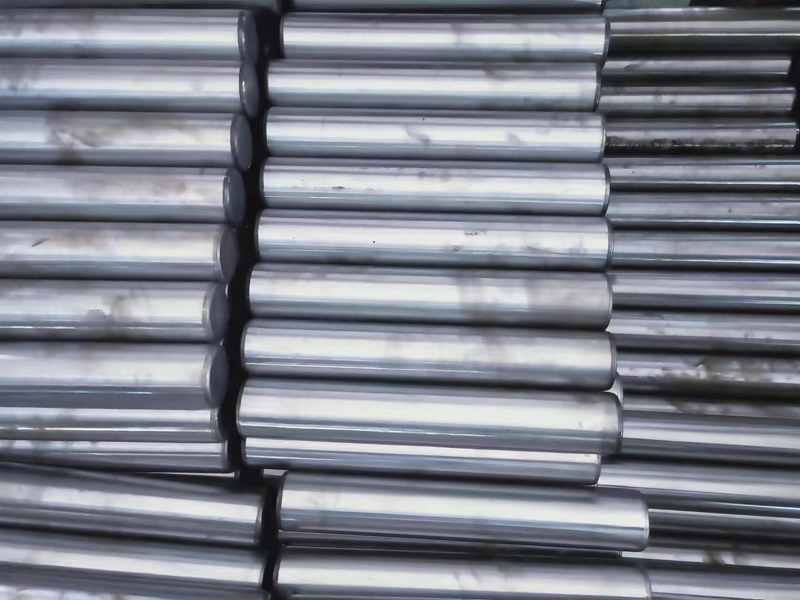

1. The chain piece has been forged, tempered and medium frequency -- scientific quenching process ensures that the core hardness of the chain piece is above HRC32, the hardness of the running rail surface is above HRC55, and it has a good metal structure.

2. Transfer to the machining workshop, where the chain piece raw material are first shot blasted, and then processed by special CNC processing equipment. Because the oil track link requires very high precision for the chain pieces, so as to ensure the sealing of the oil track link.

3. After processing, it is directly assembled with track link bushings, pins and other accessories. The stroke of each link is fixed during press-fitting, ensuring that the position of each link is consistent and the hole distance is the same.

4. Components are built with high grade steel and hardened for exceptional strength and wear life and work and wear as a system for maximum uptime and productivity.

-

-

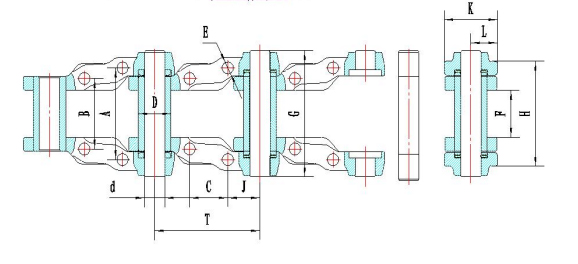

A: 178.4

B: 138.4

C: 72

T: 203

E: 20.5/19.5

| Fit for Brand | Model | ||||

| KOMATSU | D120A 18 | D125A 18 | D135A1 | D135A2 | D150A1 |

| D155A1 | D155A 2 | D155A3 | D155AX3 | D155AX5 | |

| D155AX 6 | D155C1 | D155W 1 | D20A 5 | D20A 6 | |

| D20A7 | D20P 5 | D20P 6 | D20P7 | D20PL6 | |

| D2OPLL6 | D20Q5 | D20Q6 | D20Q7 | D21A 5 | |

| D21A6 | D21A7 | D21E 6 | D21P 5 | D21P 6 | |

| D21P 6A | D21P 6B | D21P7 | D21PL6 | D21Q 6 | |

| D21Q6 | D21Q7 | D275A2 | D275A-5 | D30A 15 | |

| D31A15 | D31A 16 | D31A 17 | D31E 18 | D31P 16 | |

| D31P16A | D31P17 | D31P17A | D31P18 | D31P20 | |

| D31P20A | D31PL16 | D31PL17 | D31PL18 | D31PL20 | |

| D31PLL16 | D31PLL17 | D31PLL18 | D31PLL20 | D31PX21 | |

| D31Q16 | D31Q17 | D31Q18 | D32E1 | D32P1 | |

| D355A1 | D355A3 | D355A5 | D355C3 | D375A1 | |

| D375A2 | D375A3 | D375A5 | D375A6 | D37E1 | |

| D37E2 | D37E5 | D37EX21 | D37EX22 | D37P1 | |

| D37P2 | D37P5 | D37PX21 | D38E1 | D38P1 | |

| D39E1 | D39EX21 | D39P1 | D39PX21 | D40A1 | |

| D40A3 | D40F3 | D40P1 | D40P3 | D40PL1 | |

| D40PL3 | D40PLL1 | D40PLL3 | D41A3 | D41A3A | |

| D41E3 | D41E6 | D41P3 | D41P6 | D41Q3 | |

| D41S3 | D45A1 | D45E1 | D45P1 | D475A1 | |

| D475A2 | D50A16 | D50A17 | D50F16 | D50F17 | |

| D50P16 | D50P17 | D50PL16 | D50PL17 | D51EX-22 | |

| D51PX-22 | D53A16 | D53A17 | D53P16 | D53P17 | |

| D58E1 | D58E1A | D58E1B | D58P1 | D58P1B | |

| D60A3 | D60A6 | D60A7 | D60A8 | D60E7 | |

| D60E8 | D60F7 | D60F7A | D60F8 | D60F8A | |

| D60P3 | D60P6 | D60P7 | D60P8 | D60PL7 | |

| D60PL8 | D61EX12 | D61EX15 | D61PX12 | D61PX15 | |

| D63E1 | D63E1A | D65A6 | D65A7 | D65A8 | |

| D65E12 | D65E7 | D65E8 | D65EX12 | D65EX15 | |

| D65EX17 | D65P12 | D65P7 | D65P8 | D65PX12 | |

| D65PX15 | D65WX-15 | D68E1 | D68P1 | D75A1 | |

| D80A12 | D80A18 | D80E18 | D80F18 | D80P18 | |

| D83E1 | D83P1 | D85A12 | D85A18 | D85A21 | |

| D85A21B | D85E18 | D85E21 | D85EX15 | D85P18 | |

| D85P21 | D85PX15 | ||||

-

0102030405060708

-

01020304050607

-

010203

-

010203040506

Product Advantages

1. Crack Resistance: Through carbonization and medium-frequency quenching treatment, the bush achieves a balanced hardness in its core and abrasion resistance on both internal and external surfaces.

2. Abrasion Resistance: Tempering and medium-frequency quenching treatment of the pin ensure adequate core hardness and abrasion resistance on its external surfaces.

3. Enhanced Hardness: The track link undergoes medium-frequency hardening treatment, ensuring exceptional strength and abrasion resistance.

Why choose us

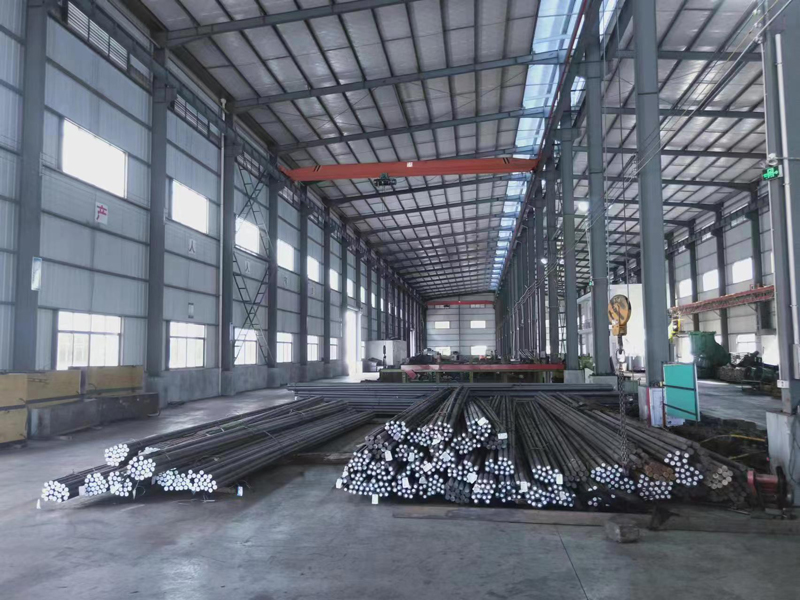

Infrastructure:

Our operations benefit from a robust technical infrastructure, enabling us to consistently deliver top-notch products to our clientele. Equipped with state-of-the-art machinery and tools, our well-appointed infrastructure empowers us to fulfill the diverse needs of our customers. Throughout the manufacturing process, as well as during packaging, our products receive meticulous oversight from our team of experts.

Employee:

Our workforce comprises proficient professionals and skilled laborers who play instrumental roles in ensuring the delivery of high-quality products. Working in harmony, our team efficiently handles tasks, facilitating the timely fulfillment of large orders for our clients.

Quality Commitment:

We maintain a dedicated team of experts overseeing product quality at every stage, from raw material procurement to final production. This meticulous approach ensures that we consistently offer a quality-assured product range backed by a 100% guarantee.

Frequently Asked Questions

1. Are you in the business of trade or manufacturing?

We function as an integrated entity overseeing both trade and manufacturing aspects. Our manufacturing base is located in Quanzhou, while our sales operations are centered in Xiamen.

2. How can I verify the compatibility of the part with my excavator?

Kindly provide us with the accurate model number, machine serial code, or any distinct identifiers on the parts themselves. Alternatively, you may choose to measure the parts and provide us with their dimensions or blueprints.

3. What are your accepted payment terms?

Typically, we favor T/T transactions, although other terms can be discussed.

4. What is the anticipated delivery time?

If the items are not available at our factory, the standard delivery time is 20 days. However, for parts in stock, we can expedite delivery within 1-7 days.

5. How do you ensure Quality Control?

We have implemented a comprehensive QC framework to uphold the quality of our products. Our dedicated team meticulously examines product quality and specifications at every stage of production, overseeing the entire process until packing is finalized to ensure product safety during transit.

description2