Products Categories

Featured Products

01

EX200-5 Top-rated Bucket Tooth OEM Logo

Meet the demands of tough digging conditions with our heavy-duty excavator bucket teeth. Expertly designed for high impact and abrasion resistance, these rugged teeth provide optimized penetration and fragmentation for efficient excavation.

Tooth Material: Material: 30CrMnSiA High strength alloy steel, heat treated to 45-55 HRC

Tip Material: Proprietary carbide alloy at 60-65 HRC

Compatibility: EX200-5 [Mention compatible excavator models and bucket widths]

product details

Key Features

1. High-Strength Alloy Steel: Heat-treated for unmatched durability and resistance to bending stresses.

2. Wear-Resistant Alloy Tips: Special alloy casted tip with advanced hardness to resist abrasive wear.

3. Secure Locking: Patented adapter and pin locking system for a tight, reliable fit.

4. Universal Fit: Compatible with OEM buckets across leading excavator brands.

-

01020304050607

-

0102030405060708

-

010203

-

010203040506

Product Advantages

1. Up to 35% longer service life compared to standard bucket teeth.

2. Maintains penetration sharpness longer for efficient digging.

3. Low risk of metal breakage or loosening failures.

4. Drop-in fit minimizes installation downtime.

About us

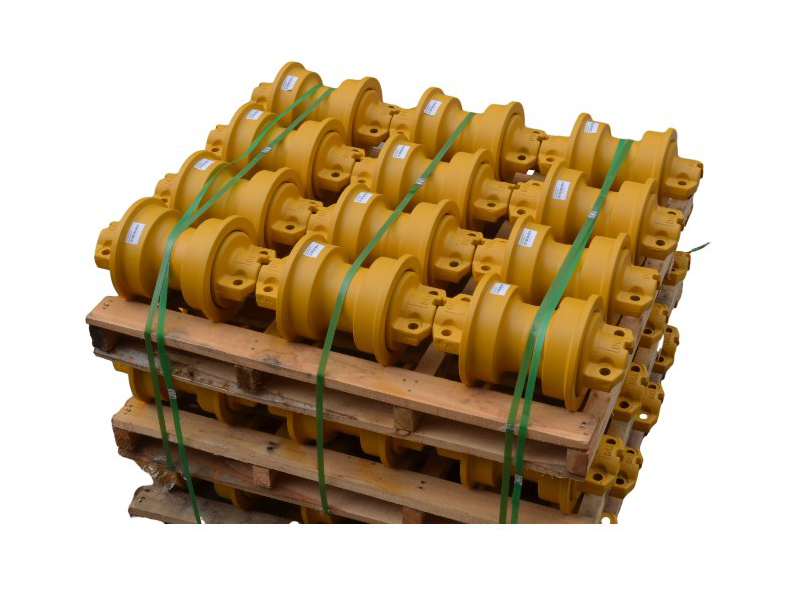

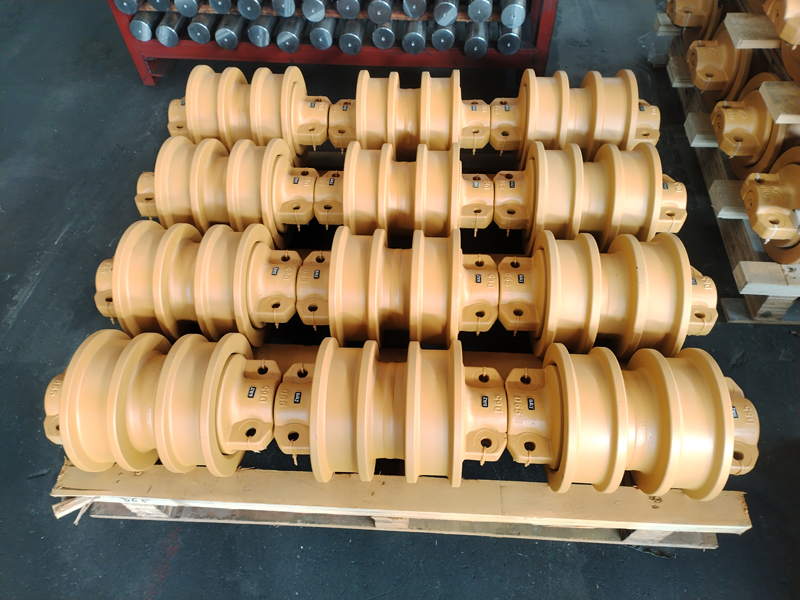

We are a factory dedicated to producing forgings and castings for construction machinery for 16 years. Our product range includes dry or oil-coated track links, track rollers, carrier rollers, idlers, sprockets (segments), track shoes, bolts, track adjuster assemblies, and other essential undercarriage accessories for excavators, bulldozers, rotary drilling rigs, and crawler cranes.

Frequently Asked Questions

1. Are you a trader or a manufacturer?

Our business model integrates both manufacturing and trading operations. Our manufacturing facility is based in Quanzhou, while our sales offices are located in Xiamen.

2. How can I verify the compatibility of the part with my excavator?

Please provide us with the accurate model number, machine serial number, or any distinctive identifiers on the parts themselves. Alternatively, you can take measurements of the parts and furnish us with dimensions or sketches.

3. What payment terms do you offer?

Typically, we accept T/T payments, although we are open to discussing alternative terms based on mutual agreement.

4. How do you maintain product quality?

Our quality control system is robust, ensuring impeccable products. Our dedicated team conducts thorough inspections of product quality and specifications at every stage of production. This oversight continues until the packing process is complete, guaranteeing the safety of the products during transit to the container.

description2