01

Bulldozer D65 Premium Carrier Roller Replacements

| Carrier roller body material: | 40Mn2/50Mn | |||

| Surface hardness: | HRC52-56 | |||

| Shaft material: | 45# | |||

| Surface hardness: | HRC55-60 | |||

| Base collar material: | QT450-10 | |||

2. The raw material used is national standard 40Mn2 steel. The steel undergoes overall quenching and tempering, as well as intermediate frequency heat treatment.This process ensures that the surface hardness can reach HRC55-60.

3. The high-standard production and processing load-bearing shaft has excellent mechanical properties against wear, high load, and high rigidity. This greatly prolongs the service life of the assembly.

-

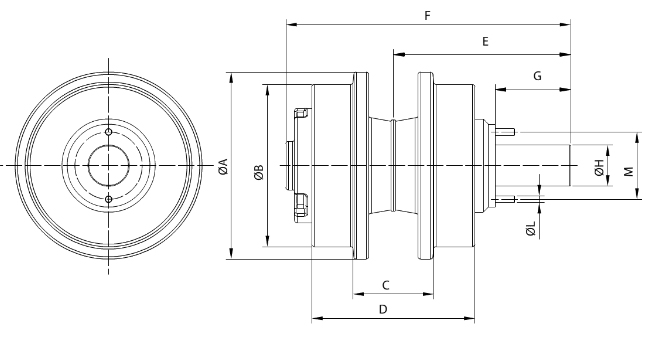

ØH: 61

| Fit for Brand | Model | ||||

| KOMATSU | D120A 18 | D125A 18 | D135A1 | D135A2 | D150A1 |

| D155A1 | D155A 2 | D155A3 | D155AX3 | D155AX5 | |

| D155AX 6 | D155C1 | D155W 1 | D20A 5 | D20A 6 | |

| D20A7 | D20P 5 | D20P 6 | D20P7 | D20PL6 | |

| D2OPLL6 | D20Q5 | D20Q6 | D20Q7 | D21A 5 | |

| D21A6 | D21A7 | D21E 6 | D21P 5 | D21P 6 | |

| D21P 6A | D21P 6B | D21P7 | D21PL6 | D21Q 6 | |

| D21Q6 | D21Q7 | D275A2 | D275A-5 | D30A 15 | |

| D31A15 | D31A 16 | D31A 17 | D31E 18 | D31P 16 | |

| D31P16A | D31P17 | D31P17A | D31P18 | D31P20 | |

| D31P20A | D31PL16 | D31PL17 | D31PL18 | D31PL20 | |

| D31PLL16 | D31PLL17 | D31PLL18 | D31PLL20 | D31PX21 | |

| D31Q16 | D31Q17 | D31Q18 | D32E1 | D32P1 | |

| D355A1 | D355A3 | D355A5 | D355C3 | D375A1 | |

| D375A2 | D375A3 | D375A5 | D375A6 | D37E1 | |

| D37E2 | D37E5 | D37EX21 | D37EX22 | D37P1 | |

| D37P2 | D37P5 | D37PX21 | D38E1 | D38P1 | |

| D39E1 | D39EX21 | D39P1 | D39PX21 | D40A1 | |

| D40A3 | D40F3 | D40P1 | D40P3 | D40PL1 | |

| D40PL3 | D40PLL1 | D40PLL3 | D41A3 | D41A3A | |

| D41E3 | D41E6 | D41P3 | D41P6 | D41Q3 | |

| D41S3 | D45A1 | D45E1 | D45P1 | D475A1 | |

| D475A2 | D50A16 | D50A17 | D50F16 | D50F17 | |

| D50P16 | D50P17 | D50PL16 | D50PL17 | D51EX-22 | |

| D51PX-22 | D53A16 | D53A17 | D53P16 | D53P17 | |

| D58E1 | D58E1A | D58E1B | D58P1 | D58P1B | |

| D60A3 | D60A6 | D60A7 | D60A8 | D60E7 | |

| D60E8 | D60F7 | D60F7A | D60F8 | D60F8A | |

| D60P3 | D60P6 | D60P7 | D60P8 | D60PL7 | |

| D60PL8 | D61EX12 | D61EX15 | D61PX12 | D61PX15 | |

| D63E1 | D63E1A | D65A6 | D65A7 | D65A8 | |

| D65E12 | D65E7 | D65E8 | D65EX12 | D65EX15 | |

| D65EX17 | D65P12 | D65P7 | D65P8 | D65PX12 | |

| D65PX15 | D65WX-15 | D68E1 | D68P1 | D75A1 | |

| D80A12 | D80A18 | D80E18 | D80F18 | D80P18 | |

| D83E1 | D83P1 | D85A12 | D85A18 | D85A21 | |

| D85A21B | D85E18 | D85E21 | D85EX15 | D85P18 | |

| D85P21 | D85PX15 | ||||

-

010203040506

-

01020304050607

-

010203

-

010203040506

Product Advantages

1. Sturdy Build: Crafted from high-strength materials, our Bulldozer Carrier Rollers boast a robust construction that stands up to the demands of heavy loads, ensuring durability and an extended operational life.

2. Advanced Sealing: Employing a sophisticated sealed design, our Bulldozer Carrier Rollers shield internal components from contaminants, including dust and moisture.

3. User-Friendly Maintenance: Designed with the user in mind, these carrier rollers make maintenance tasks straightforward, contributing to a smoother overall operational experience for your bulldozer.

About Us

We are the factory specializing in the production of construction machinery forgings and castings all year round. Our main products include dry/oil track links, track rollers, carrier rollers, idlers, sprockets (segments), track shoes, bolts, track adjuster assembly and other undercarriage accessories for the excavators, bulldozers, rotary drilling rigs and crawler cranes.

Frequently Asked Questions

1. Are you involved in trading or manufacturing?

We are the manufacturer provide both trading and manufacturing operations. Our manufacturing hub is based in Quanzhou, while our sales division operates out of Xiamen.

2. How can I confirm the compatibility of the part with my bulldozer?

Kindly furnish us with the accurate model number, machine serial code, or any distinctive identifiers on the parts themselves. Alternatively, you may opt to measure the parts and provide us with their dimensions or schematics.

3. What are your payment terms?

Typically, we adhere to T/T transactions, although alternative terms are open for discussion.

4. What is the expected delivery time?

If the items are unavailable at our factory, the standard delivery duration is 20 days. However, for parts in stock, we can expedite delivery within 1-7 days.

5. How do you ensure Quality Control?

We have implemented a comprehensive QC framework to uphold the quality of our products. Our dedicated team meticulously inspects product quality and specifications at each stage of production, overseeing the entire process until packing is completed to ensure product safety during transit.

description2